Compactors for Sale (241)

There are compaction machines large and small listed under the ‘Compactors’ category here at Plant Pages. These include rollers that the operator walks behind to large, double drum rollers for compacting road surfacing and single drum compactors used on waste sites. The most common compactor for sale here are the double drum rollers from manufacturers such as Hamm, Bomag and Ammann whilst the smaller plate compacting machines tend to be fewer and farther between. Use the sub categories to drill down to the machine that you are looking for.

Latest Compactors News

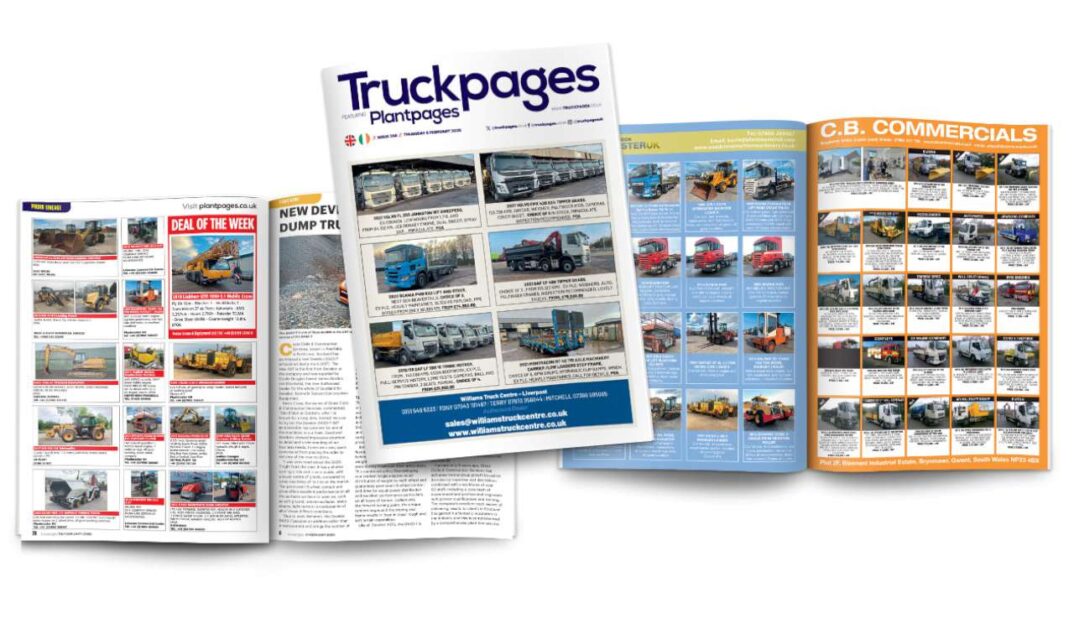

Truck & Plant Pages Issue 258 is out now

Any business involved in road building and repair should take a look at the range of trucks on this week’s front cover. From DAF Hot Boxes to Volvo Johnston sweepers to tipper grabs and tri-axle low loaders, Williams Truck Centre have you covered. Check out their stock online at www.williamstruckcentre.com Check out the news pages...

First New JCB CT430-140 Tandem Roller Rolls off Production Line

A leading road surfacing specialist has purchased the first new JCB CT430-140 compaction model to roll off the production line. Purchased by Royston, Hertfordshire-based North Herts Surfacing, the brand new tandem vibratory roller is already in action on local authority highways maintenance contracts for Ringway Jacobs on Essex highways and EST in Hertfordshire. North Herts...

Ammann Improves Their Advanced Intelligent Compaction system – ACEpro

Ammann has upgraded its advanced Intelligent Compaction system, ACEpro, to make it easier for operators to access the built-in technology. The enhanced system is being integrated into Ammann ARP 75 and ARP 75 C Pivot-Steer Tandem Rollers. Ammann Compaction Expert (ACE), the company’s proprietary automatic measurement, control and documentation system, was first launched in 1998....

Ammann Delivers Machine Sustainability with eMission

Ammann’s environmentally friendly solution for machines, eMission, is integrated into new Ammann products. It starts with reduced emissions – and incorporates efficiency, productivity and lower maintenance demands that make job sites healthier and business owners more profitable. ECOdrop Initiative Ammann has also taken efforts to incorporate sustainable improvements across their product line through the ECOdrop...

Truck & Plant Pages Issue 240 is out now

If you are looking for a compactor with a compaction rate of around 50 tonnes, (let’s face it, we all are at some point or other), then the 2012 model Dynapac CC362 D single drum vibratory roller on the front cover should be up your street. Even better news is that Plantmaster have four examples...